- Inicio

- Productos

- Tubos termoretráctiles

- Tubo termorretráctil de pared doble

- Tubo termorretráctil con adhesivo 4:1, semirígido

Tubo termorretráctil con adhesivo 4:1, semirígido

Modelo: CB- DWT (3000)

Materiales

Capa exterior: Unión de cruce de resina de poliolefina modificada.

Capa interior: Adhesivo termofusible

Índice de contracción: 4:1

Aplicaciones

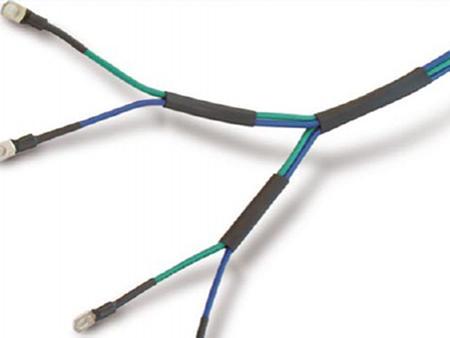

Este modelo de tubo termocontraíble es de tipo semirígido con adhesivo 4:1, tiene característica de resistencia en diesel el cual es indispensable para aplicaciones en el rubro automotriz como sellado de aislamiento para cables de arnés de carro, protección de cables ante cualquier fricción, liberación de tensión para terminales y empalmes de cables.

| P/N | As supplied (mm) | After recovery | ||

| Min. inside diameter | Max. inside diameter | Total wall | Min. adhesive wall | |

| CB-DWT(3000)-1 | 5.72 | 1.27 | 1.2 | 0.56 |

| CB-DWT(3000)-2 | 7.44 | 1.65 | 1.52 | 0.76 |

| CB-DWT(3000)-3 | 10.85 | 2.41 | 1.91 | 1.02 |

| CB-DWT(3000)-4 | 17.78 | 4.45 | 2.41 | 1.37 |

| Item | Test method | Standard | Specifications |

| Longitudinal shrinkage | ASTM D2671 | 0-10% | 5% |

| Tensile strength | ASTM D2671 | ≥10.3MPa | 18.87MPa |

| Elongation at break | ASTM D4.3.1.2 | ≥250% | 330% |

| Scan modulus | ASTM D2671 | ≥137MPa | 370MPa |

| Heat shock | 250±3℃,4h | No dripping, flowing or cracking | Pass |

| Dynamic cut through (KG) | ASTM D3032 | 13.6kg | Pass |

| Volume resistivity | ASTM D2671 | ≥1.0×1012Ω.cm | 9.0×1014Ω.cm |

| Flammability | ASTM D2863 | ≥28 | 29 |

| RT-1112 | 30s self-extinguish | Pass | |

| Dielectric voltage | 2500V,60s | No breakdown | Pass |

| Tensile strength after aging | ASTM D2671 | ≥6.9MPa | 11.0MPa |

| Oil resistance | 97#petrol 23±3℃,24h 100℃±3℃,1h IRM902#oil IRM903#oil hydraulic fluids | No cracking | Pass |

| P/N | As supplied (mm) | After recovery | ||

| Min. inside diameter | Max. inside diameter | Total wall | Min. adhesive wall | |

| CB-DWT(3000)-1 | 5.72 | 1.27 | 1.20 | 0.56 |

| CB-DWT(3000)-2 | 7.44 | 1.65 | 1.52 | 0.76 |

| CB-DWT(3000)-3 | 10.85 | 2.41 | 1.91 | 1.02 |

| CB-DWT(3000)-4 | 17.78 | 4.45 | 2.41 | 1.37 |

- Este tipo de tubo termoretráctil permite usar y envolver en cables de gran diámetro gracias a su índice de contracción.

- Este modelo es de tipo semirígido adhesivo 4:1, tiene propiedades importantes como el tener retardante de flama y ser libre de halógenos cumpliendo con los términos dados por RoHS. Gracias a todas estas características expuestas nos permite usarlo para el rubro automotriz por ser de tipo ecológico o eco ambiental, siendo además resistente al diesel.

- Este tipo de tubo termocontraíble tiene una capa gruesa de adhesivo termofusible, brindando un gran sellado evitando los fluidos y la humedad.

- El rango de temperatura de operación va desde los 40 ºC a los 135 ºC. (La contracción comienza desde 110 ºC y se completa en los 135 ºC).

Tubo termorretráctil de pared doble

Consulta